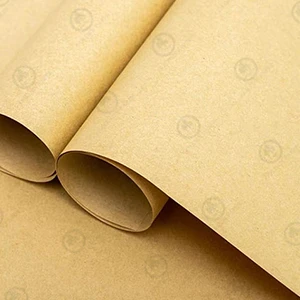

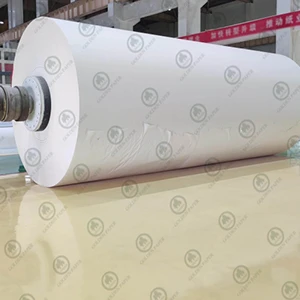

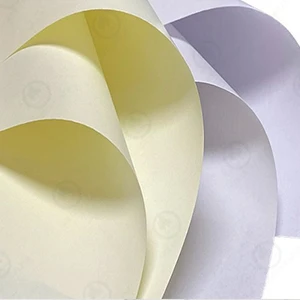

Coated duplex board with grey back, with a grey base and a white coating on the front. This type of board is widely used for color box printing in the packaging industry, particularly suited for single-sided printing. Due to its simple and elegant design, coated duplex board with grey back can not only enhance the class of packaging products but also possesses many superior performances, making it an important material in the packaging industry.

Characteristics and Grading of Coated Duplex Board with Grey Back

The characteristics of coated duplex board with grey back lie in its smooth surface, rough texture, and strong ink absorption. It has good compressive strength and wear resistance, making it a commonly used high-quality material in the packaging industry. Common applications include single-layer boxes, corrugated boxes, paper cards, tags, etc. Depending on the quality and thickness of the coated side of the coated duplex board with grey back, it is usually divided into A-grade, B-grade, C-grade, E-grade, and F-grade.

A-grade coated duplex board with grey back: The best quality, suitable for packaging applications with higher requirements.

B-grade and C-grade coated duplex board with grey back: Suitable for products with moderate quality requirements.

E-grade and F-grade coated duplex board with grey back: Lower quality, suitable for simple packaging or lower-end needs.

With this grading system, buyers can select the appropriate product according to their needs to ensure the effectiveness of applications in different scenarios.

Advantages of Coated Duplex Board with Grey Back

As a traditional paper product, coated duplex board with grey back still maintains irreplaceable advantages.

Low Cost: Compared to other high-quality packaging paper, coated duplex board with grey back is lower in cost, making it suitable for large-scale production and application.

Lightweight and High Strength: Despite being lightweight, its strength and durability are excellent, meeting the general requirements for packaging and printing.

Good Environmental Performance: Coated duplex board with grey back has good recyclability, can be recycled, and aligns with current environmental trends.

These features make coated duplex board with grey back widely used in various industries, especially in the packaging industry, as a popular choice for balancing cost control and performance.

Environmental Upgrades Driven by Coated Duplex Board with Grey Back

With increasing environmental requirements, the production process of coated duplex board with grey back from reliable coated paper board manufacturers is continuously optimized to reduce its environmental impact. Below are some major directions for environmental upgrades:

Material Selection: Using renewable and degradable materials such as waste paper and bamboo to replace traditional wood. This not only reduces dependence on forest resources but also lowers the environmental impact of raw materials.

Production Process Optimization: By improving production processes to reduce energy and material consumption. Employing more advanced pulping technology to increase pulp yield, thus reducing resource waste and environmental pollution.

Environmental Technology Application: Introducing advanced environmental technologies such as membrane separation technology and advanced oxidation technology for deep treatment of wastewater produced during production to reduce pollutant emissions.

Product Structure Adjustment: Adjusting the weight and thickness of the paperboard without affecting its performance to reduce raw material consumption, thereby achieving energy savings and emission reductions.

Waste Resource Utilization: Strengthening the recycling and utilization of waste materials, reusing waste paper and pulp produced during production to reduce waste emissions.

These upgrades not only improve the environmental performance of coated duplex board with grey back but also help manufacturing enterprises better cope with increasingly stringent environmental policies.

In today's context of rising environmental requirements, the production of coated duplex board with grey back is also continuously optimized, developing towards a more environmentally friendly and sustainable direction. For enterprises needing high-quality coated duplex board with grey back, choosing the right supplier is crucial. Golden Paper Group, established for over 20 years, specializes in the production and export of pulp, paper, and paperboard products. It is committed to sustainable development, providing high-quality products that meet environmental requirements.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id