Greaseproof baking paper, as the name suggests, is paper that can effectively prevent the penetration of grease. Its emergence and development originate from a serendipitous discovery in the 1930s. Over time, the technology of greaseproof baking paper has continually innovated, gradually becoming an indispensable part of the food industry and domestic kitchens. Today's greaseproof baking paper has undergone nearly a century of evolution, not only upgrading in material and function but also playing a crucial role in practical applications.

The Evolution of Greaseproof Baking Paper Materials

The history of greaseproof baking paper began with an accidental discovery in the 1930s. At that time, a bakery owner named Joseph Smith in Brooklyn, New York, read an experimental article about wax paper's oil-resistance properties in a newspaper, which prompted him to improve the traditional baking mats. After generations of technical improvements, today's greaseproof baking paper is very different. Initially, greaseproof baking paper primarily used paraffin coatings, but with technological progress and the development of materials science, the materials for greaseproof baking paper have gradually changed.

Currently, greaseproof baking paper on the market usually adopts a honeycomb fiber structure, which is similar to the water absorption mechanism of rice paper but achieves one-way penetration through a silicone oil coating. This way, the grease can be securely locked in while moisture freely evaporates. This material innovation not only improves the oil-resistance effect but also ensures that the greaseproof baking paper can be used in high-temperature environments without deformation or leakage.

Functional Segmentation of Greaseproof Baking Paper

With diverse special paper market demands, the functions of greaseproof baking paper have gradually become more specialized. Taking different cooking needs as an example, the size and thickness of greaseproof baking paper have significantly changed. Greaseproof baking paper varies in size to suit different cooking scenarios. For example, baking enthusiasts prefer small-sized sheets of 18 cm square, while commercial kitchens tend to use rectangular sheets of 28 x 38 cm, which are very suitable for standard commercial baking pans.

In addition to changes in size, the thickness of greaseproof baking paper also varies greatly. The lightweight version of 22 g/m² is suitable for short-term high-temperature baking, while the thicker version of 42 g/m² is specially used for long-term high-temperature treatments like frying. Some users even choose to stack different weights of paper to create a composite effect similar to that of rice paper and silk mounting, greatly enhancing the oil-resistance effect.

Market Innovations in Greaseproof Baking Paper

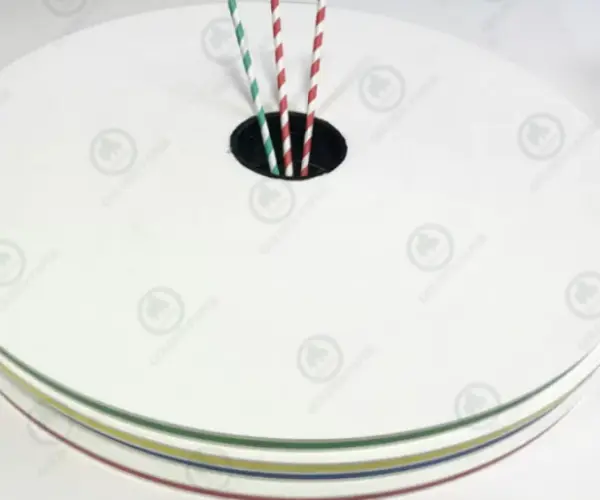

Besides size and thickness, the design form of greaseproof baking paper has also seen many innovations. Some brands on the market have launched greaseproof baking paper with serrated lace edges, not just for decoration. In fact, the 3D embossing extending to the edge of the baking pan can increase the sliding coefficient by 15%, reducing the overflow of grease in the baking pan. This design cleverly combines practicality and aesthetics, showcasing continuous innovation in the functionality of greaseproof baking paper.

With continuous technological advancements, the materials and functions of greaseproof baking paper are constantly being updated and optimized. If you are looking for high-quality greaseproof baking paper, Golden Paper Group is your ideal choice. Golden Paper Group offers professional greaseproof baking paper products suitable for various baking, frying, and dining scenes.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id